How to install heat shrink tubing?

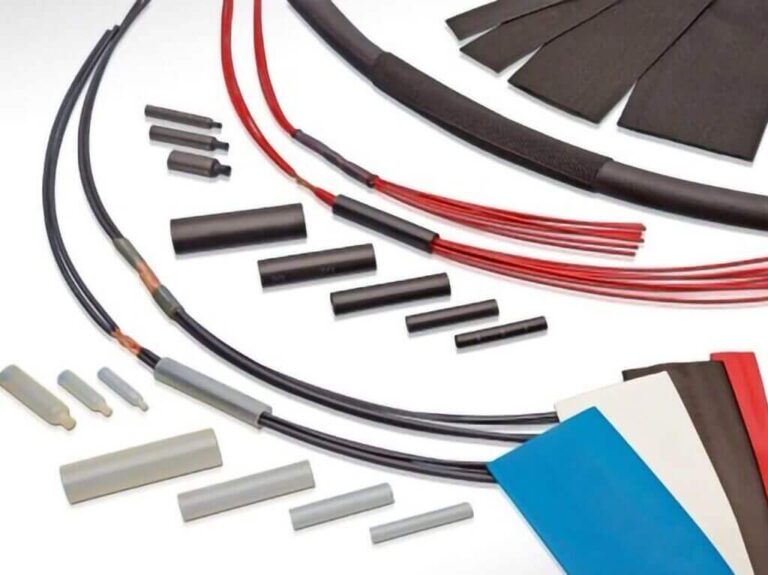

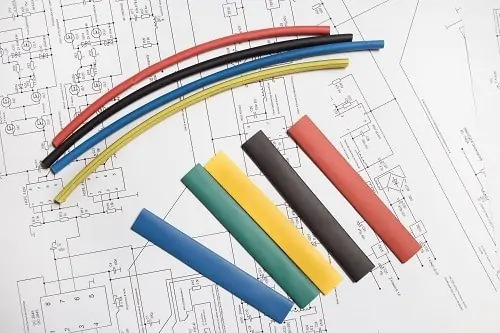

1. To prepare materials, first understand the size of the cable diameter, or calculate the corresponding diameter from the length and width, and select the heat shrinkable tube whose diameter is slightly larger than the cable diameter.

2. Remove the burrs and sharp corners on the cable to prevent cracks caused by piercing the heat shrink tube during the retraction process. The quick drying detergent must be used in advance to clean the oil and impurities at the cable connections and keep them clean.

3. Calculate the length to be wound, and cut the corresponding length of heat shrink tube. When cutting the radiator pipe, the cut shall be neat and smooth, without burrs or cracks, so as to avoid stress concentration and propagation along the cracks during heating and contraction.

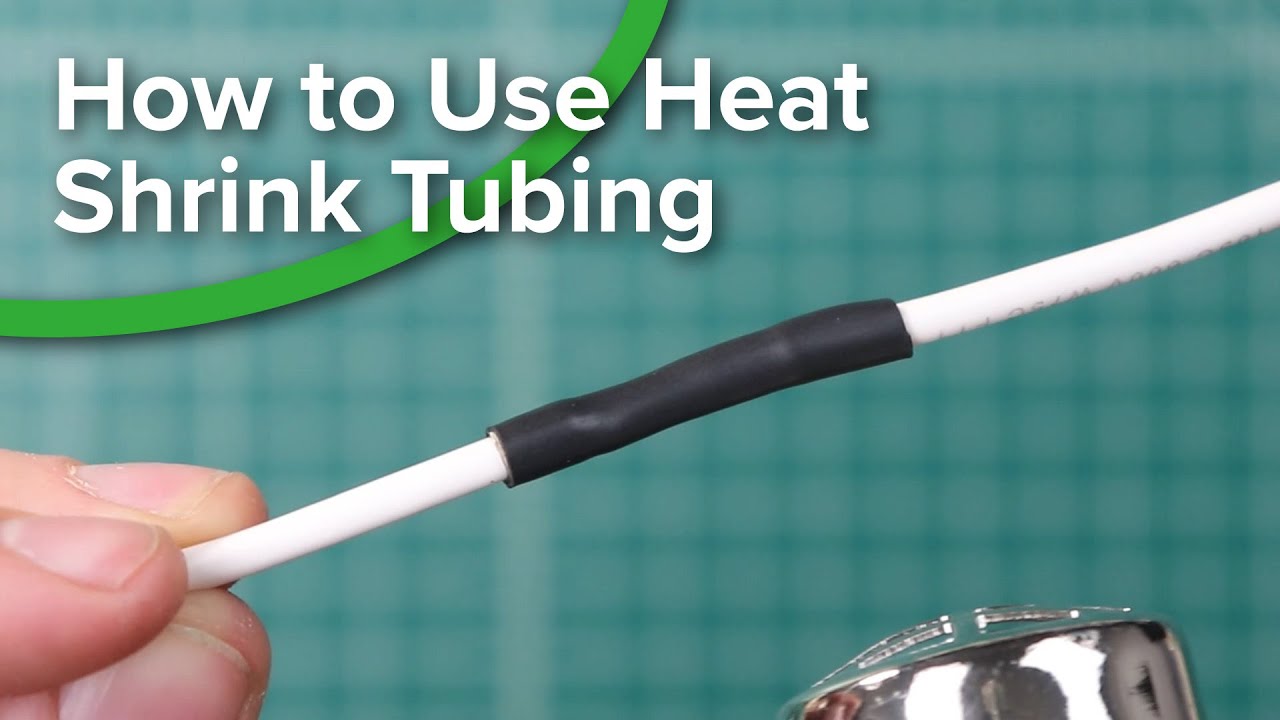

4. Slide the heat shrink tube into one end of the cable and move the wrapped heat shrink tube to a suitable position. For bent cables, arrange heat shrinkable tubes at the corners to prevent wrinkles.

5. The heating tools are generally hot air guns, ovens or hair dryers. In the heating process, it shall be heated from left to right or from right to left in a single direction. It can also be heated from the middle to both ends to avoid residual air in the heat shrink tube. After shrinking, wrap the cable tightly, and do not heat it too close to the surface of the sleeve or concentrate it in one place, otherwise the thickness will be uneven or the sleeve will be burned.